Safety and quality – Made in Germany.

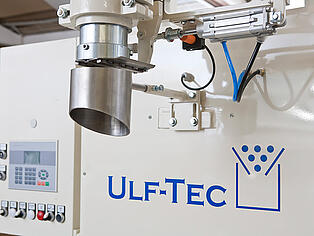

Screw feeder.

Maximum precision with the utmost flexibility are among ULF-Tec's greatest strengths. These attributes also apply to the ULF-Tec screw feeder. Maintenance-friendly and service-friendly, as well as being easy to clean, it is also convincing in the most demanding applications.

Products and Fields of Application

- Filling of powder products

Types of Bag and Packaging

- Sealable stand-up bags

- Suitable for paper packaging and plastic packaging

- Other materials on request

Options and equipment

- Extended bag magazine (max. 2 m, runtime of approx. 35 m without refilling of the bag)

- Data capture systems for production and downtimes

- Film group packers

- Paper packers

- Checkweighers

- Metal detectors

- Modem for remote maintenance

- Maintenance agreements

- Forming trolley for storing a forming set

Basic construction

Above the screw feeder is a feeder screw, the inlet of which is attached to a product storage container. The dispensing screw and a mixer are located in the funnel. Sieves and cones adapted perfectly to the product ensure weighing accuracy that is as tolerance-free as possible, as well as interruption-free production. All of the parts of the ULF-Tec screw feeder are made in the very highest quality and reliably comply with product requirements (food-safe, etc.). Thanks to their high quality and resilience, this machine is exceptionally long-lasting.

![[Translate to Englisch:] Schneckendosierer Absperrklappe](/fileadmin/_processed_/a/6/csm_Schneckendosierer_Absperrklappe-1_800x600_5fe96100ca.jpg)

![[Translate to Englisch:] Schneckendosierer Schaltkasten](/fileadmin/_processed_/d/2/csm_Schneckendosierer_Schaltkasten-1_800x600_866b9b84f7.jpg)

![[Translate to Englisch:] Schneckendosierer Seitenansicht](/fileadmin/_processed_/3/a/csm_Schneckendosierer_Seitenansicht-1_800x600_27a9831e8e.jpg)

![[Translate to Englisch:] Schneckendosierer Komplettansicht](/fileadmin/_processed_/4/b/csm_Schneckendosierer_Komplettansicht-1_800x600_5ef8eee6f4.jpg)

![[Translate to Englisch:] Technische Zeichnung des Schneckendosierers](/fileadmin/_processed_/1/5/csm_UM-DS-ST_Auger_Filler-1_09c14f474f.jpg)